|

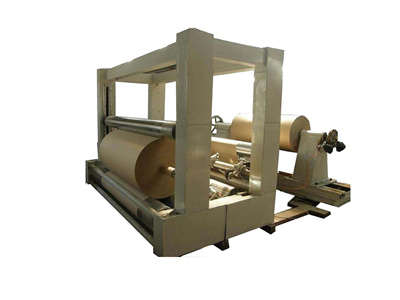

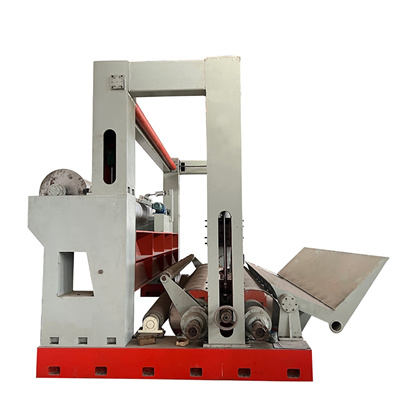

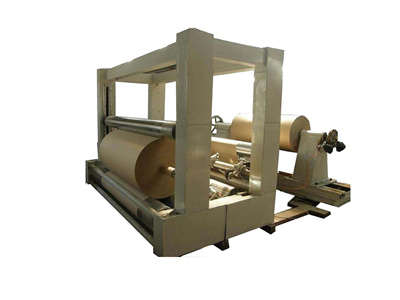

Jumbo roll size: Max.Ø1500 ×(15750-5000) Finished roll diameter: Ø 1000-1500mm Speed: Max.2200m/min Slitting width: at least 70mm PLC controlled, automatic log output

|

The purpose of a rewinder is to rewind the paper rolls (referred to as raw paper rolls) produced by a paper machine one by one, and the rewinded paper is made into finished paper. Replacing DC drive with AC drive for rewinder has become a development trend in the paper machinery industry. The paper roll rolled up by the paper roll is relatively soft and may be damaged or cracked internally. The edges on both sides are not neat, and the width of the paper web cannot be directly used for paper processing or printing machines. Most types of paper (such as newsprint, letterpress printing paper, packaging paper, etc.) must be trimmed, cut, spliced, and re rolled on the paper roll core to form finished paper rolls with certain specifications and specifications. Sealing requirements before leaving the factory.

This slitting rewinder machine is used to slitting various paper roll from the industrial jumbo rolls into narrow with jumbo rolls. It is an ideal and core equipment for paper converting factory and paper mill. The working speed is 300-2200m/min, the slitting precise is high and slitting width is adjustable. We have exported to many countries with good feedback.

MAIN COMPONENTS

1. Frame unit

2. Bottom roller

3. Guide and spreader unit

4. Vertical cutting unit

5. Hydraulic tension unit

6. Paper feeding unit

7. Unwinding frame unit

8. Driving equipment

9. Hydraulic system

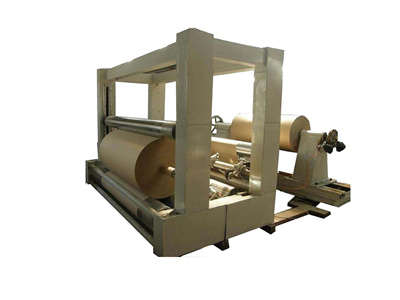

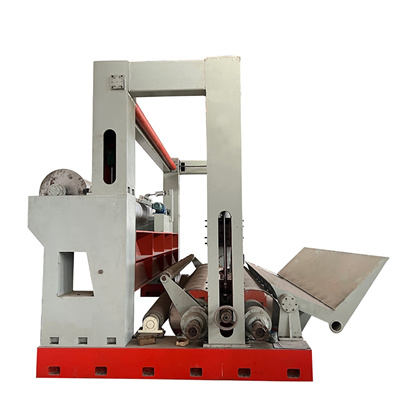

Jumbo roll size: Max.Ø1500 ×(15750-5000)

Finished roll diameter: Ø 1000-1500mm

Speed: Max.2200m/min

Slitting width: at least 70mm

PLC controlled, automatic log output

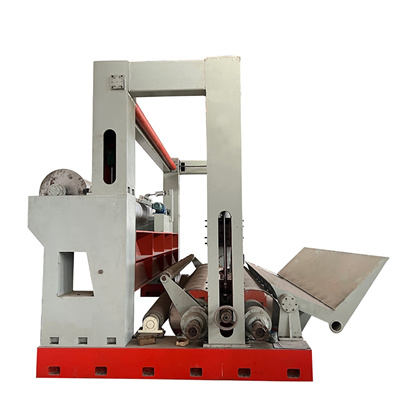

The purpose of a rewinder is to rewind the paper rolls (referred to as raw paper rolls) produced by a paper machine one by one, and the rewinded paper is made into finished paper. Replacing DC drive with AC drive for rewinder has become a development trend in the paper machinery industry. The paper roll rolled up by the paper roll is relatively soft and may be damaged or cracked internally. The edges on both sides are not neat, and the width of the paper web cannot be directly used for paper processing or printing machines. Most types of paper (such as newsprint, letterpress printing paper, packaging paper, etc.) must be trimmed, cut, spliced, and re rolled on the paper roll core to form finished paper rolls with certain specifications and specifications. Sealing requirements before leaving the factory.

This slitting rewinder machine is used to slitting various paper roll from the industrial jumbo rolls into narrow with jumbo rolls. It is an ideal and core equipment for paper converting factory and paper mill. The working speed is 300-2200m/min, the slitting precise is high and slitting width is adjustable. We have exported to many countries with good feedback.

MAIN COMPONENTS

1. Frame unit

2. Bottom roller

3. Guide and spreader unit

4. Vertical cutting unit

5. Hydraulic tension unit

6. Paper feeding unit

7. Unwinding frame unit

8. Driving equipment

9. Hydraulic system

中文

中文

中文

>

中文

>

中文

中文