|

Trim width:1575-5000 mm Diameter of sizing roll:Φ550-φ1100 mm Angle of slope of loading:30°,15° Design speed:600m/min Surface hardness of sizing roll:Shore "A" 95 ±2,Shore "A" 100±2 Loading type:Pneumatic tyre loading Working speed:200-500m/min Max .linear pressure:30N/mm Drive system:Arrange with the paper machine drive system

|

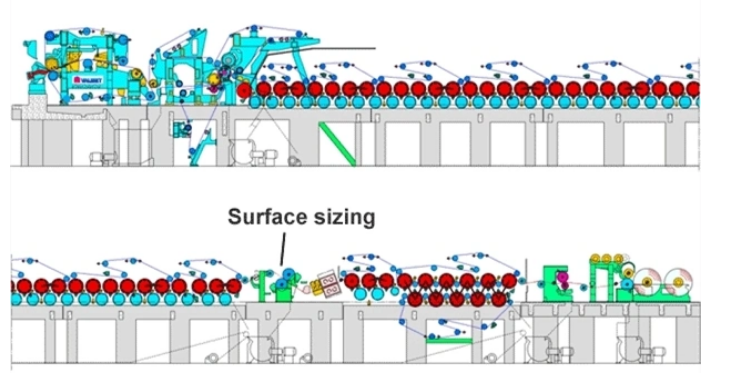

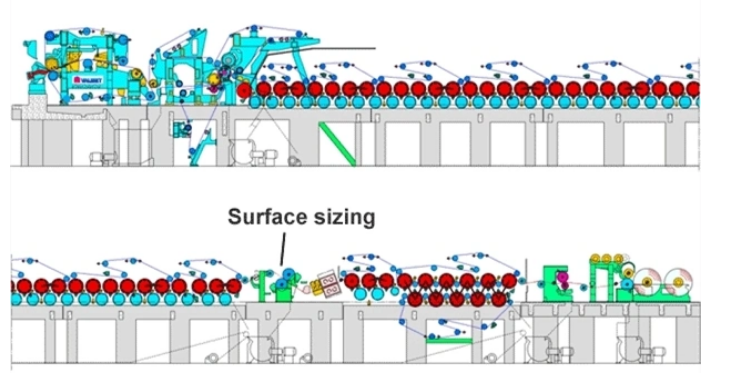

The surface sizing machine is a paper machine accessory equipment in the papermaking process. After applying glue to the surface of paper, it enriches the gaps between paper fibers, improves the physical properties of the paper, and significantly improves the paper properties, permeability, and surface coverage, thereby improving the grade of the paper.

There are two types of sizing machines: horizontal and oblique. The purpose of surface sizing is to prevent liquid penetration, obtain better surface properties and improve physical properties of paper (such as surface strength and internal binding force), which is an effective means to improve the performance of base paper.

Surface sizing is commonly used on grades of paper and board that will be coated and/or printed. The traditional purposes of surface sizing have been to improve the sheet's resistance to the penetration of fluids and to improve certain sheet properties. Traditionally, a starch-based sizing solution is applied to both sides of a fully dried sheet in a two-roll nip at a "size press" that is located between drying sections.

The surface size press is the paper machine corollary equipment. After sizing for the paper surface, it could enrich the interspace between paper fibers and increase the paper physical property. After drying, calendaring, it could increase the glossiness of the paper web surface and improve the paper grade. The drive system of the surface size press is in the paper machine. The up and down sizing roll all with the drive. After loading, according to the paper technological requirements, press the chemical glue between the two rolls into the paper. Then the paper is sent to the next process through the bottom spreader roll.

The sizing machine is suitable for high speed printing and packaging paper machines, as well as various functional coating of special paper and sizing of paper without mill blade.

Benefits

1.No consumables

2.High starch penetration

3.Easy maintenance operations

Trim width:1575-5000 mm

Diameter of sizing roll:Φ550-φ1100 mm

Angle of slope of loading:30°,15°

Design speed:600m/min

Surface hardness of sizing roll:Shore "A" 95 ±2,Shore "A" 100±2

Loading type:Pneumatic tyre loading

Working speed:200-500m/min

Max .linear pressure:30N/mm

Drive system:Arrange with the paper machine drive system

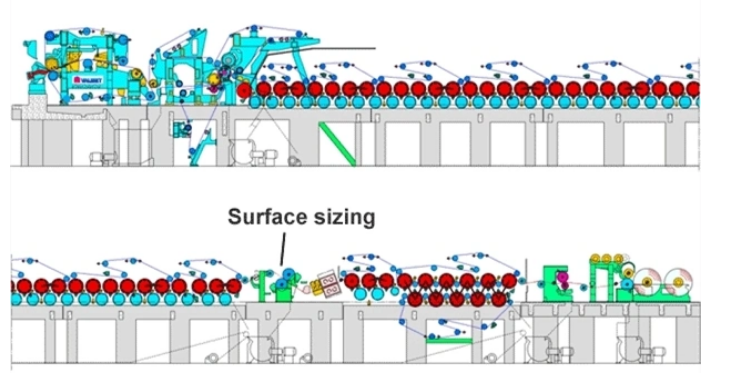

The surface sizing machine is a paper machine accessory equipment in the papermaking process. After applying glue to the surface of paper, it enriches the gaps between paper fibers, improves the physical properties of the paper, and significantly improves the paper properties, permeability, and surface coverage, thereby improving the grade of the paper.

There are two types of sizing machines: horizontal and oblique. The purpose of surface sizing is to prevent liquid penetration, obtain better surface properties and improve physical properties of paper (such as surface strength and internal binding force), which is an effective means to improve the performance of base paper.

Surface sizing is commonly used on grades of paper and board that will be coated and/or printed. The traditional purposes of surface sizing have been to improve the sheet's resistance to the penetration of fluids and to improve certain sheet properties. Traditionally, a starch-based sizing solution is applied to both sides of a fully dried sheet in a two-roll nip at a "size press" that is located between drying sections.

The surface size press is the paper machine corollary equipment. After sizing for the paper surface, it could enrich the interspace between paper fibers and increase the paper physical property. After drying, calendaring, it could increase the glossiness of the paper web surface and improve the paper grade. The drive system of the surface size press is in the paper machine. The up and down sizing roll all with the drive. After loading, according to the paper technological requirements, press the chemical glue between the two rolls into the paper. Then the paper is sent to the next process through the bottom spreader roll.

The sizing machine is suitable for high speed printing and packaging paper machines, as well as various functional coating of special paper and sizing of paper without mill blade.

Benefits

1.No consumables

2.High starch penetration

3.Easy maintenance operations

中文

中文

中文

>

中文

>

中文

中文