|

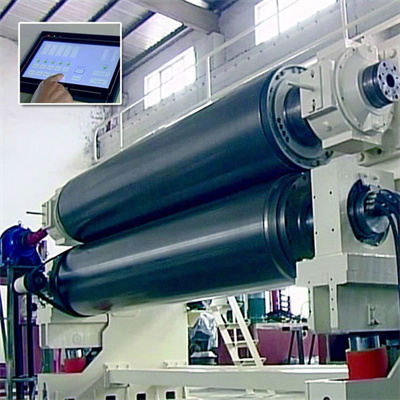

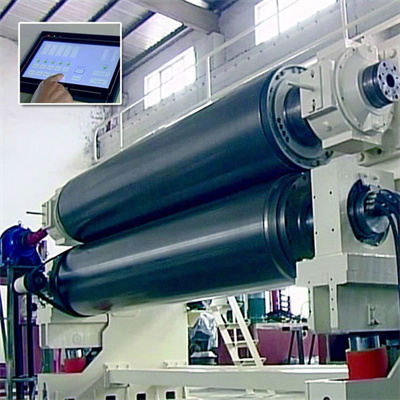

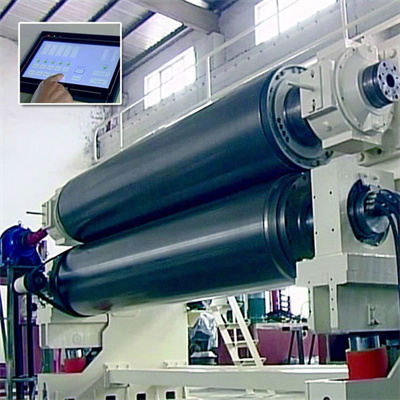

Paper Web:1880-10000 mm Speed:50-1000 m/Min Linear pressure:50-300 kN/m Temperature:180 ºC Max. Structure:Hard/Soft Calender (Crowning Adjustable)

|

Calender is applied to the repeated processing process between the surface of the roller and the surface of the coarse paper after the paper comes out of the drying section. The function of soft calendering is to make the paper smooth through hot pressing. Soft calender replaces ordinary calender and super calender by increasing the surface temperature and gap width of the rollers to replace the repeated linear pressure of multiple rollers, achieving the calendering effect.

When pressurizing, elastic deformation of soft roll leads to surface contact between hard roll and soft roll. The surface contact width of soft calender is 10-25 mm, which is 15 times wider than that of a hard calendering machine. The unit pressure of the soft calendering machine is generally 20-40 N/mm2, which is just 1/2-1/4 of that of the hard calendering machine. Owing to the wide nip, the sheet stays longer in the nip and the energy consumption converts into heat which passes to the paper and makes the paper fiber plastify. The softened fiber is easier to be calendered, thus increasing smoothness. The rebound resilience of surface material enables the soft roll surface to suit any bad flatness of sheet, so the soft calendering machine can achieve better softness than common hard calendering machines. Color spots can be eliminated and printability is greatly improved. Another advantage of the soft calendering machine is paper sheet can be in motion with high moisture under the condition of elimination of paper blackening and color spots. The temperature, nip pressure, width and number of the soft calender all have impact on the calendering effect.

Paper Web:1880-10000 mm

Speed:50-1000 m/Min

Linear pressure:50-300 kN/m

Temperature:180 ºC Max.

Structure:Hard/Soft Calender (Crowning Adjustable)

Calender is applied to the repeated processing process between the surface of the roller and the surface of the coarse paper after the paper comes out of the drying section. The function of soft calendering is to make the paper smooth through hot pressing. Soft calender replaces ordinary calender and super calender by increasing the surface temperature and gap width of the rollers to replace the repeated linear pressure of multiple rollers, achieving the calendering effect.

When pressurizing, elastic deformation of soft roll leads to surface contact between hard roll and soft roll. The surface contact width of soft calender is 10-25 mm, which is 15 times wider than that of a hard calendering machine. The unit pressure of the soft calendering machine is generally 20-40 N/mm2, which is just 1/2-1/4 of that of the hard calendering machine. Owing to the wide nip, the sheet stays longer in the nip and the energy consumption converts into heat which passes to the paper and makes the paper fiber plastify. The softened fiber is easier to be calendered, thus increasing smoothness. The rebound resilience of surface material enables the soft roll surface to suit any bad flatness of sheet, so the soft calendering machine can achieve better softness than common hard calendering machines. Color spots can be eliminated and printability is greatly improved. Another advantage of the soft calendering machine is paper sheet can be in motion with high moisture under the condition of elimination of paper blackening and color spots. The temperature, nip pressure, width and number of the soft calender all have impact on the calendering effect.

中文

中文

中文

>

中文

>

中文

中文