|

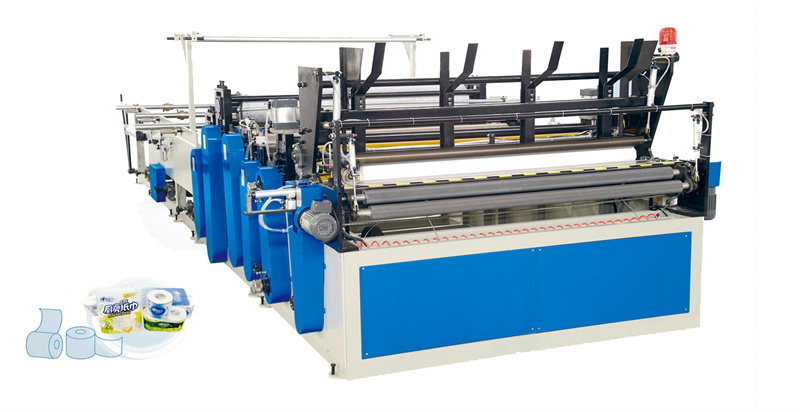

Parent roll width:2100mm Parent roll diameter:Up to Φ1300mm Core inside diameter of parent Roll:3"(76mm)or as requested by customer Machine speed:0-260m/min depending on model Finished roll outside diameter:60-130mm Perforation pitch:Adjustable Sheet count:Increasing every sheet Core outside diameter of finished rolls:Φ35-50mm Parent roll:1-4 ply,15-30 gsm Installed power:7.5Kw-15Kw

|

1.For paper width up to 2100mm to make bathroom tissue,equipped with variable perforation length system to fit any length need. The speed of this rewinder is up to 260m/min, including:back-stands,embosser units, rewinder. for jumbo rolls up to 1300mm diameter, and with a pneumatic loading of jumbo roll system.

2.This model machine will automatically change logs and unload the finished products,and automatically trim and seal the tails of logs,leaving a lip about 20mm to make it easy for consumers to start using the rolls without tearing the paper at the seal.

3.All the driven system to be by means of timing belts, nylon belts and gears, for years of free maintenance. Electrical eves will be mounted on the different parts of the line to monitor the machine and stop it in case it runs out of paper cores or any other unforeseen problems. The lubrication systems will be provided on the major parts of the line

4.The motor power is 7.5kW.Variable frequency control depending on the final specifications and requirements

5.This line is to be controlled by a PLC of your choice.

Parent roll width:2100mm

Parent roll diameter:Up to Φ1300mm

Core inside diameter of parent

Roll:3"(76mm)or as requested by customer

Machine speed:0-260m/min depending on model

Finished roll outside diameter:60-130mm

Perforation pitch:Adjustable

Sheet count:Increasing every sheet

Core outside diameter of finished rolls:Φ35-50mm

Parent roll:1-4 ply,15-30 gsm

Installed power:7.5Kw-15Kw

1.For paper width up to 2100mm to make bathroom tissue,equipped with variable perforation length system to fit any length need. The speed of this rewinder is up to 260m/min, including:back-stands,embosser units, rewinder. for jumbo rolls up to 1300mm diameter, and with a pneumatic loading of jumbo roll system.

2.This model machine will automatically change logs and unload the finished products,and automatically trim and seal the tails of logs,leaving a lip about 20mm to make it easy for consumers to start using the rolls without tearing the paper at the seal.

3.All the driven system to be by means of timing belts, nylon belts and gears, for years of free maintenance. Electrical eves will be mounted on the different parts of the line to monitor the machine and stop it in case it runs out of paper cores or any other unforeseen problems. The lubrication systems will be provided on the major parts of the line

4.The motor power is 7.5kW.Variable frequency control depending on the final specifications and requirements

5.This line is to be controlled by a PLC of your choice.

中文

中文

中文

>

中文

>

中文

中文