|

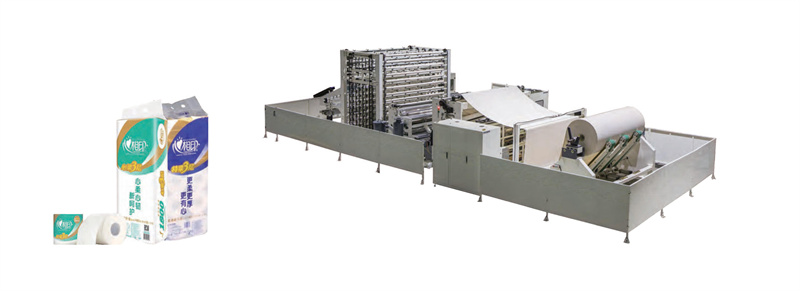

Jumbo roll width:2000-3500mm (Other size to be specified) Jumbo roll diameter:Φ1500-2800mm Speed:0-200m/min, 0-350m/min Rewind type:Non stop Finished roll core diameter:35mm--50mm, Other size to be specified Paper core input automatically:Servo motor control paper core into the rewinding area Broken paper detection:Automatic Embossing unit:steel to felt / wool / rubber / steel Edge-embossing:Air bag Control:PLC, Inverter, Mechatronics Back-stand:1-4 ply, with shaft or shaft-less |

1.Non-stop type machine, continuously rewind;

2.The whole machine is controlled by Siemens system, with high degree of automation and convenient operation.

3.Each unit is controlled by an independent motor or servo motor to ensure accurate operation;

4.The blade shaft and roller adopt high-precision

5.PLC programming control, large-screen interface operation, photoelectric integrated control another international advanced technology, can automatically detect and adjust each action of the production line.

6.Embossed system, lamination system and paper core conveying system are optional.

JG-200 High speed core winding machine

JGC Automatic core conveyor

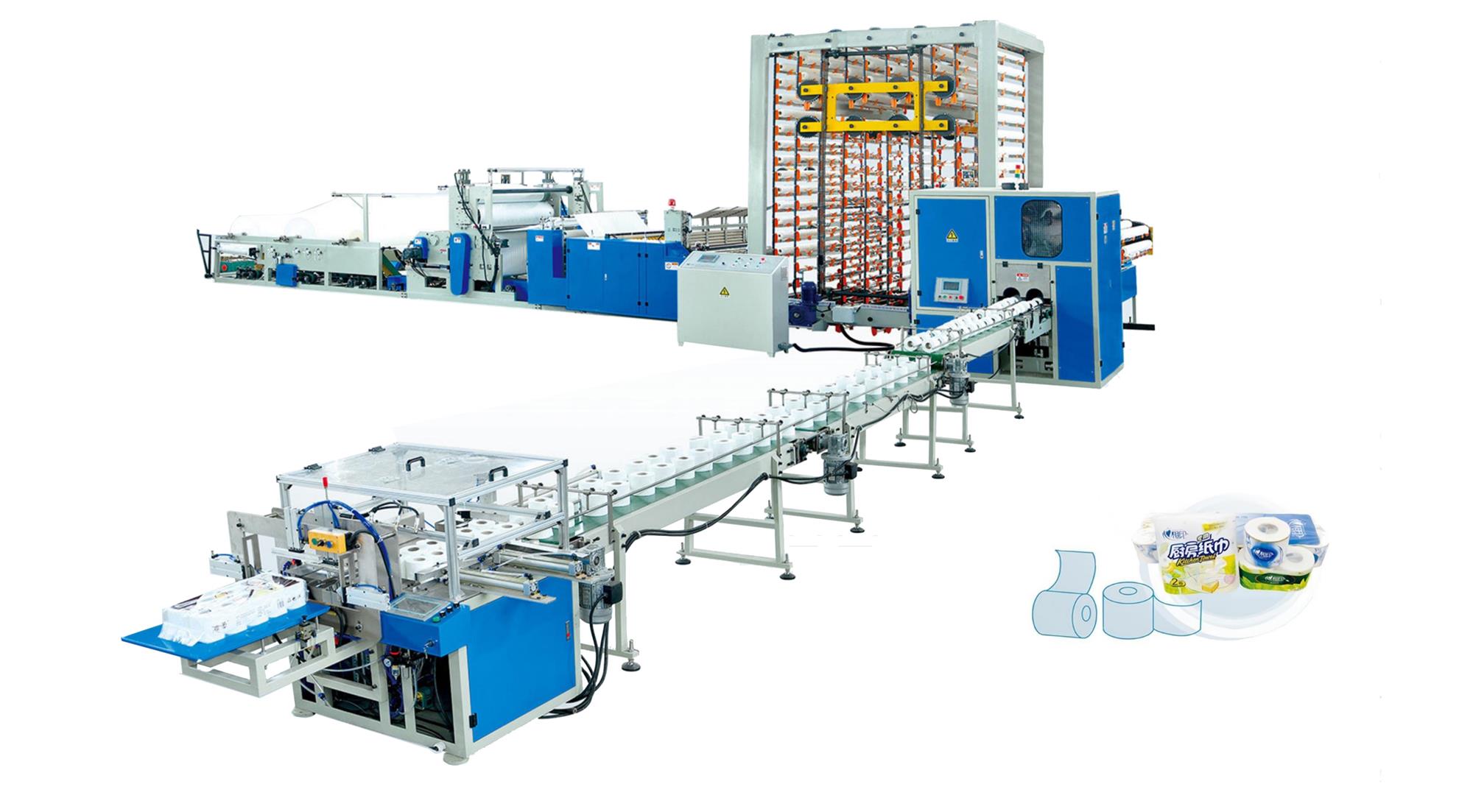

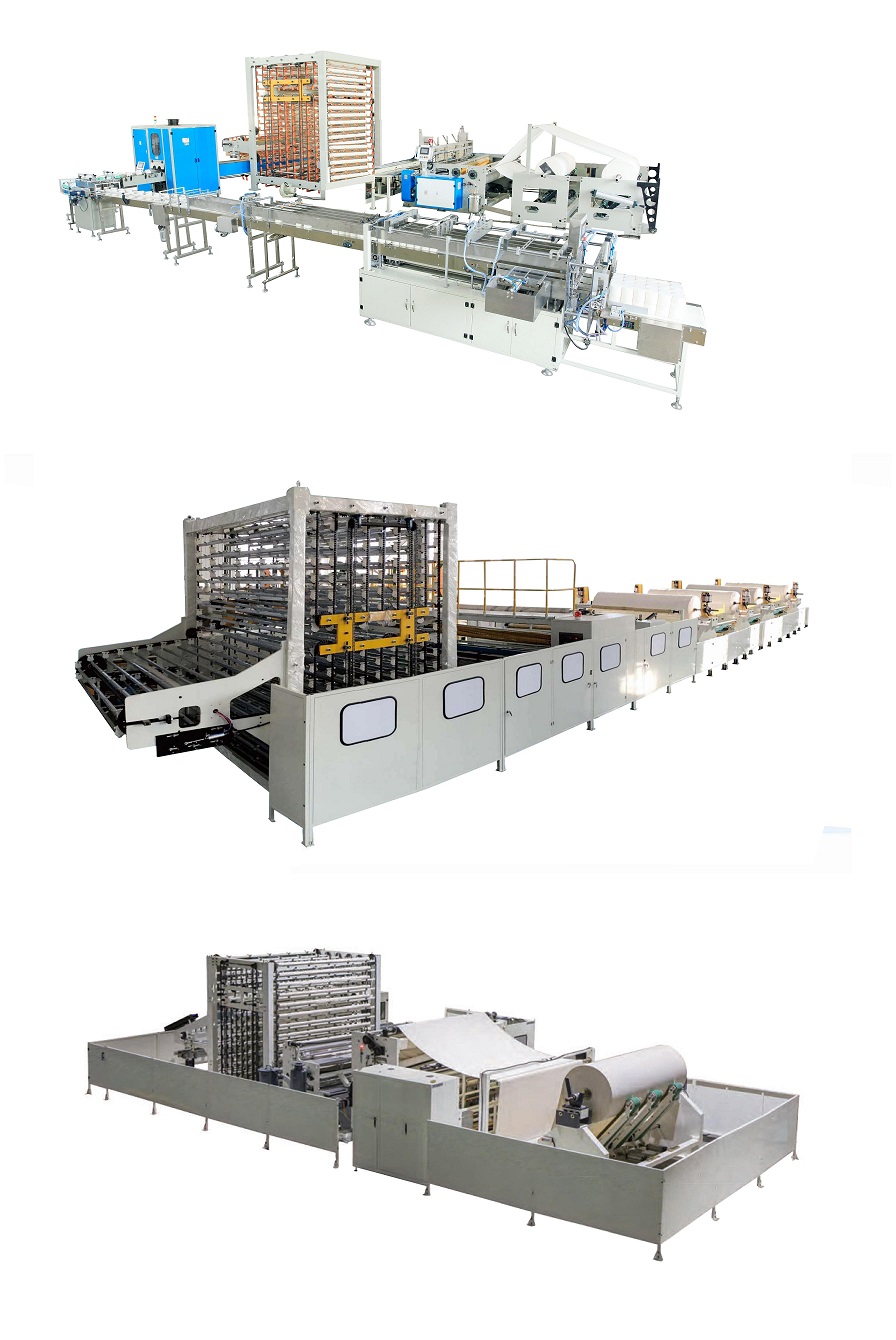

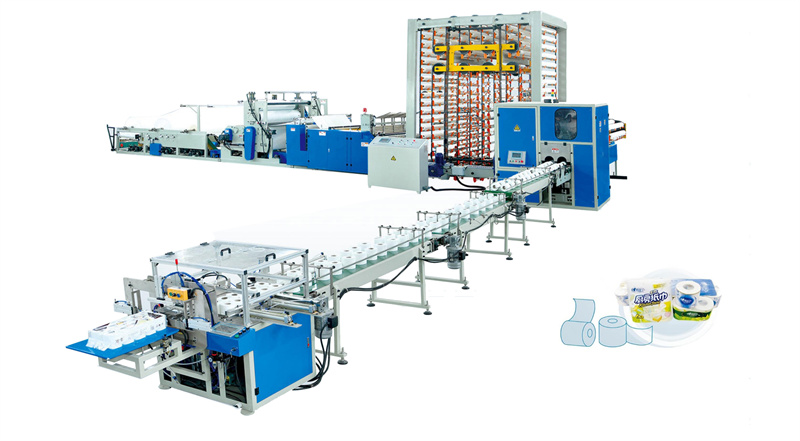

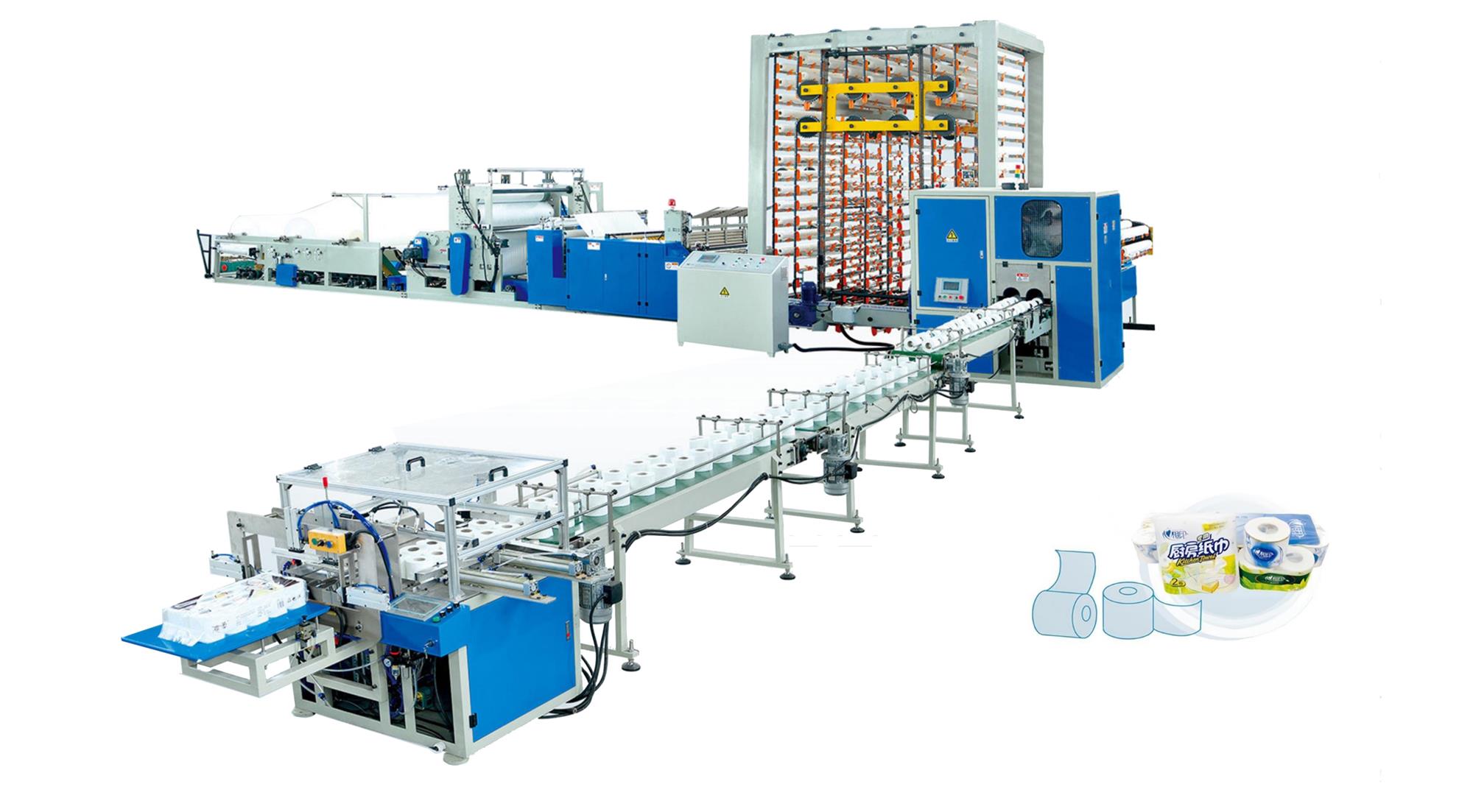

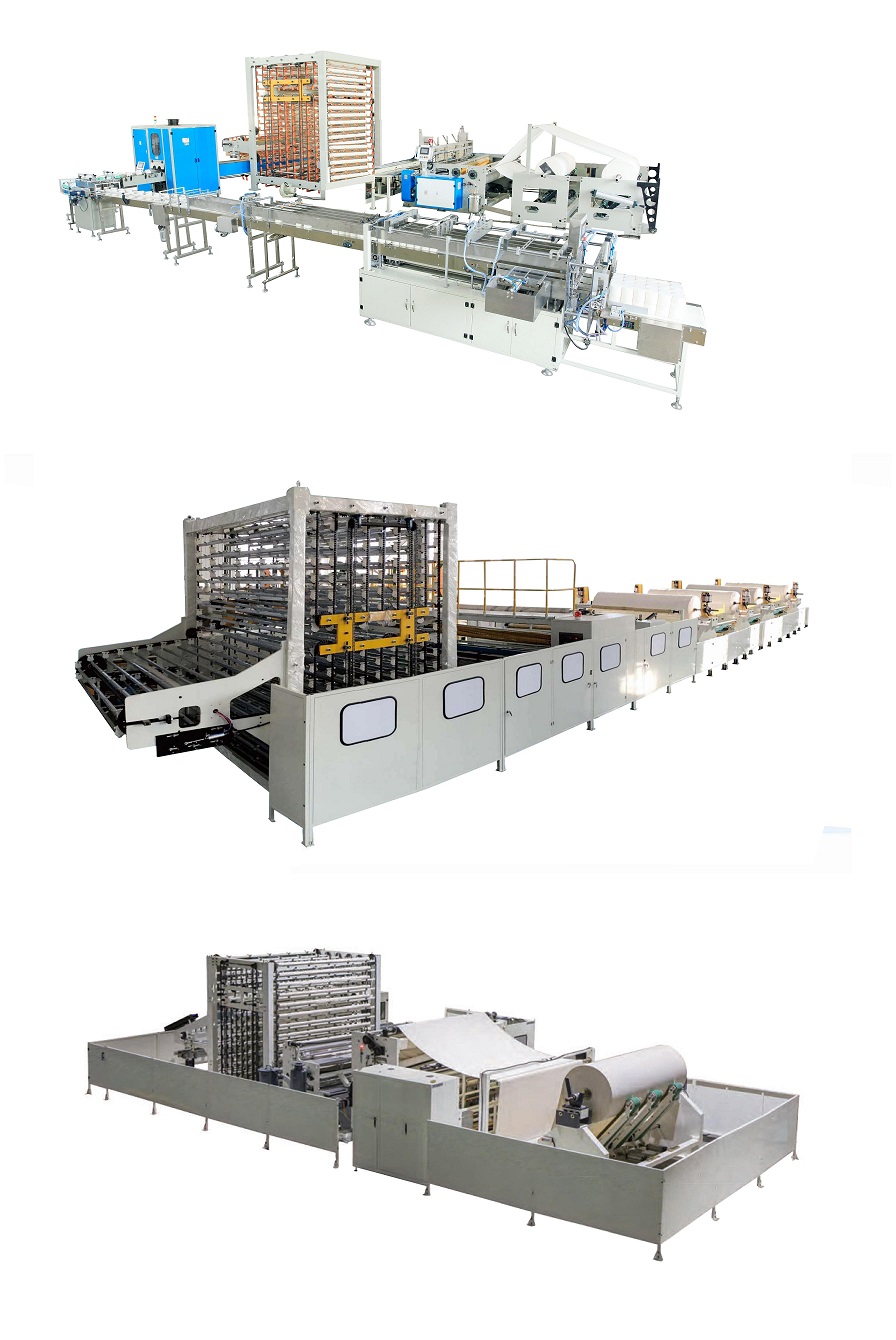

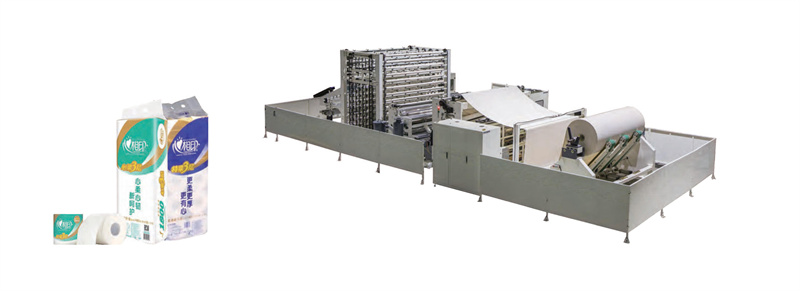

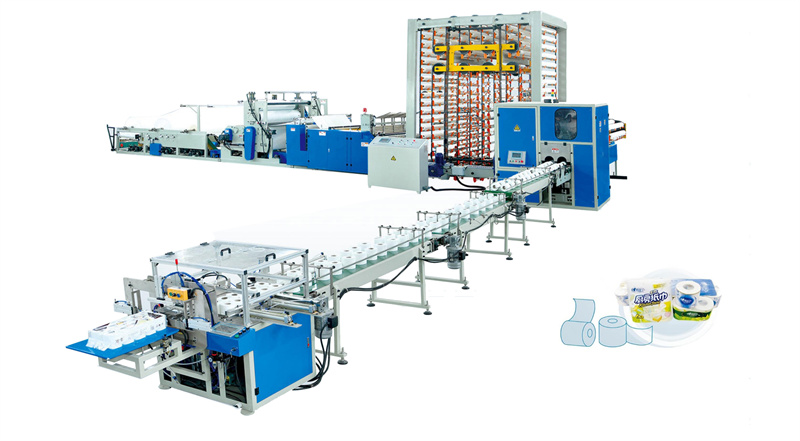

HF Fully automatic high speed toilet paper /kitchen towel production line

C-180 Accumulator

HX Log saw cutter(1/2/3 lanes)

FB-100 Single roll packing machine

DB-25A Multi-roll packaging machine

Item:Specifications

Jumbo roll width:2000-3500mm(Other size to be specified)

Jumbo roll diameter:Φ1500-2800mm

Speed:0-200m/min, 0-350m/min

Rewind type:Non stop

Finished roll core diameter:35mm--50mm, Other size to be specified

Paper core input automatically:Servo motor control paper core into the rewinding area

Broken paper detection:Automatic

Embossing unit:steel to felt / wool / rubber / steel

Edge-embossing:Air bag

Control:PLC、Inverter、Mechatronics

Back-stand:1-4 ply, with shaft or shaft-less

1.Non-stop type machine, continuously rewind;

2.The whole machine is controlled by Siemens system, with high degree of automation and convenient operation.

3.Each unit is controlled by an independent motor or servo motor to ensure accurate operation;

4.The blade shaft and roller adopt high-precision

5.PLC programming control, large-screen interface operation, photoelectric integrated control another international advanced technology, can automatically detect and adjust each action of the production line.

6.Embossed system, lamination system and paper core conveying system are optional.

JG-200 High speed core winding machine

JGC Automatic core conveyor

HF Fully automatic high speed toilet paper /kitchen towel production line

C-180 Accumulator

HX Log saw cutter(1/2/3 lanes)

FB-100 Single roll packing machine

DB-25A Multi-roll packaging machine

中文

中文

中文

>

中文

>

中文

中文