|

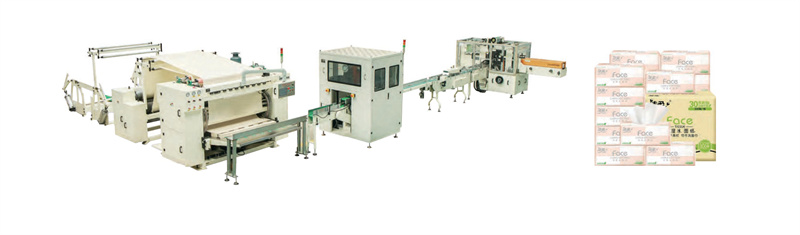

MJ-C Facial Folder adopt advanced PLC programmable control technology,variable speed adjustment and touch button multi-menu type LCD screen operation control panel. And we independently developed long-distance communication service system.It can detect the machine running at any time. The whole machine adopts timing belt driving,steeples speed adjustment. It's make the machines can fit more requirements of kinds of raw material. It improves the quality and speed. |

1.Steel to steel or steel to rubber embossing roller, pneumatically separating.

2.Pneumatic jumbo roll loading, pneumatic paper driving, steeples speed adjustment, and web tension control.

3.Equipped with Roots Type vacuum pump for stable running of the machine.

4.Pneumatic dot slitting and full slitting are available for various products width.

5.Equipped with edge embossing unit to keep the plies together

6.Jumbo roll guiding system available.

7.The machine will stop when the paper broken. It avoid waste caused by no paper or paper broken.

8.The web can be threaded on the machine by the two jog buttons, It's more safety and easier to thread the web.

Machine Model:MJ-C-1050-2000

Finished Products Unfolded Size:180x200mm(Other sizes are available)

Raw Material Diameter:Φ1300 mm(Other sizes are available)

Raw Material Core Diameter:76.2 mm(Other sizes are available)

Speed:0-100m/min

Program control:PLC Program Control

Counting system:Alternate stack by stack/ink count

Main Motor Power:5.5-11KW Frequency conversion speed regulator,5.5-11 kw

Vacuum suction unit:11-32KW

Pneumatic System:3 HP air compressor,min pressure 5kg/cm2 Pa(Provided by client)

Dimension(LxWxH):6370x(1780-2080)x2130(mm)

Weight:4500-7500kg

Option:

Program control:Program Control (PLC), LCD screen operation panel

Power:Frequency conversion speed

Driving system:Timing belt, motor

Slitting unit:Pneumatic dot slitting

Edge Embossing:Steel to steel, independent adjustment

Vacuum suction unit:Roots type vacuum pump

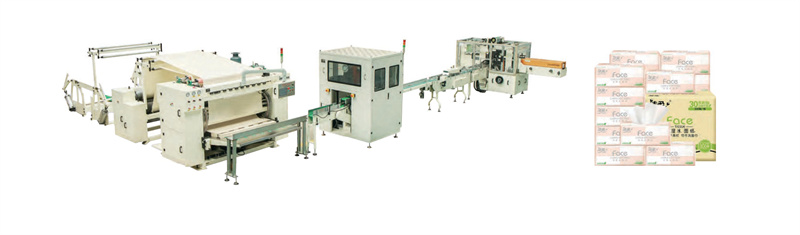

MJ-C Facial Folder adopt advanced PLC programmable control technology,variable speed adjustment and touch button multi-menu type LCD screen operation control panel. And we independently developed long-distance communication service system.It can detect the machine running at any time. The whole machine adopts timing belt driving,steeples speed adjustment. It's make the machines can fit more requirements of kinds of raw material. It improves the quality and speed.

1.Steel to steel or steel to rubber embossing roller, pneumatically separating.

2.Pneumatic jumbo roll loading, pneumatic paper driving, steeples speed adjustment, and web tension control.

3.Equipped with Roots Type vacuum pump for stable running of the machine.

4.Pneumatic dot slitting and full slitting are available for various products width.

5.Equipped with edge embossing unit to keep the plies together

6.Jumbo roll guiding system available.

7.The machine will stop when the paper broken. It avoid waste caused by no paper or paper broken.

8.The web can be threaded on the machine by the two jog buttons, It's more safety and easier to thread the web.

Machine Model:MJ-C-1050-2000

Finished Products Unfolded Size:180x200mm(Other sizes are available)

Raw Material Diameter:Φ1300 mm(Other sizes are available)

Raw Material Core Diameter:76.2 mm(Other sizes are available)

Speed:0-100m/min

Program control:PLC Program Control

Counting system:Alternate stack by stack/ink count

Main Motor Power:5.5-11KW Frequency conversion speed regulator,5.5-11 kw

Vacuum suction unit:11-32KW

Pneumatic System:3 HP air compressor,min pressure 5kg/cm2 Pa(Provided by client)

Dimension(LxWxH):6370x(1780-2080)x2130(mm)

Weight:4500-7500kg

Option:

Program control:Program Control (PLC), LCD screen operation panel

Power:Frequency conversion speed

Driving system:Timing belt, motor

Slitting unit:Pneumatic dot slitting

Edge Embossing:Steel to steel, independent adjustment

Vacuum suction unit:Roots type vacuum pump

中文

中文

中文

>

中文

>

中文

中文