|

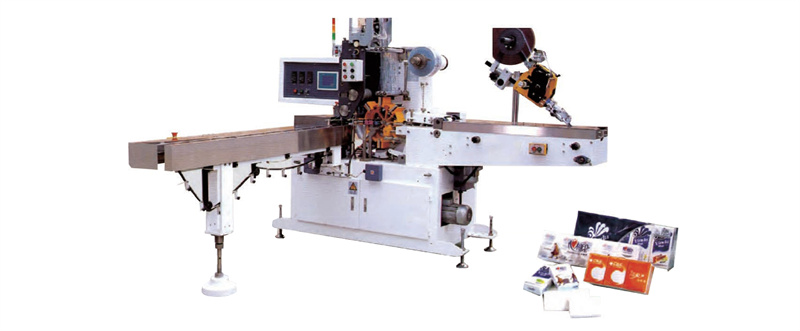

Model:SPB-S201 Automatic Hanky Wrapper Packing size & Sheet Per Pack:Regular hanky: 105x53x26mm @ 10 sheets/pack Mini Hanky: 75x53x26mm @ 10 sheets/pack Packing Film Size:Regular hanky: 150mm Mini Hanky: 116mm Capacity:60~90 packs/min Power Consumption:Main Motor: 1.1KW Output edge sealing motor: 0.18KW Heating: 3.4KW Air Pressure:0.3-0.4Mpa Dimension(LxWxH):3660x2750x1920mm Power:380V, 50Hz Machine Weight:1500kg * Other specs are available to your requirement*

|

1.High speed, stable running, and simple operation.

2.The whole machine is controlled by Siemens Program Controller (PLC), with HITACHI Touching Button type control panel and trouble shooting indication system.

3.Equipped with automatic paper break detecting and alarming system, which can help to find out the causes and the positions of the problems as soon as possible, and to remedy them right way.

4.High precision OMRON photocells to auto track the packaging material.

5.The driving system is equipped with advanced frequency converting speed control, periodically checked by high precision indexing boxes, and the various working positions are well timed with precise cam assembly.

6.Automatic lubrication oil feeding and lubricating system, which can greatly improve the performance and life of the machine.

7.Equipped with imported static relieving unit, which can make the machine performance much more stable.

8.Equipped with imported computerized temperature controller, to facilitate the easy control of working temperature.

The packing of regular hankies, mini hankies and regular square products with plastic films

Devices available:

1.Imported automatic sticker machine

2.Ribbon coder

Model:SPB-S201 Automatic Hanky Wrapper

Packing size & Sheet Per Pack:Regular hanky: 105x53x26mm @ 10 sheets/pack

Mini Hanky: 75x53x26mm @ 10 sheets/pack

Packing Film Size:Regular hanky: 150mm

Mini Hanky: 116mm

Capacity:60~90 packs/min

Power Consumption:Main Motor: 1.1KW

Output edge sealing motor: 0.18KW

Heating: 3.4KW

Air Pressure:0.3-0.4Mpa

Dimension(LxWxH):3660x2750x1920mm

Power:380V, 50Hz

Machine Weight:1500kg

* Other specs are available to your requirement*

1.High speed, stable running, and simple operation.

2.The whole machine is controlled by Siemens Program Controller (PLC), with HITACHI Touching Button type control panel and trouble shooting indication system.

3.Equipped with automatic paper break detecting and alarming system, which can help to find out the causes and the positions of the problems as soon as possible, and to remedy them right way.

4.High precision OMRON photocells to auto track the packaging material.

5.The driving system is equipped with advanced frequency converting speed control, periodically checked by high precision indexing boxes, and the various working positions are well timed with precise cam assembly.

6.Automatic lubrication oil feeding and lubricating system, which can greatly improve the performance and life of the machine.

7.Equipped with imported static relieving unit, which can make the machine performance much more stable.

8.Equipped with imported computerized temperature controller, to facilitate the easy control of working temperature.

The packing of regular hankies, mini hankies and regular square products with plastic films

Devices available:

1.Imported automatic sticker machine

2.Ribbon coder

中文

中文

中文

>

中文

>

中文

中文