|

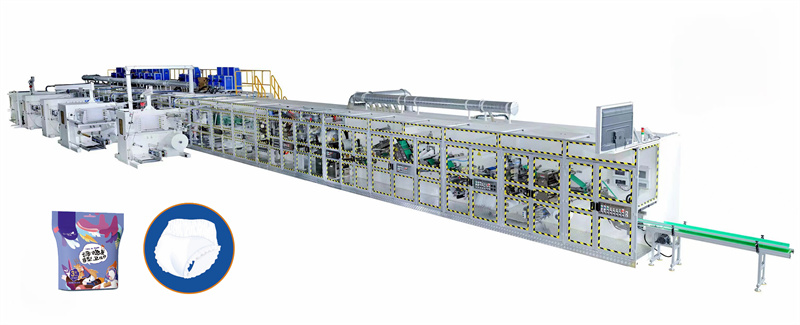

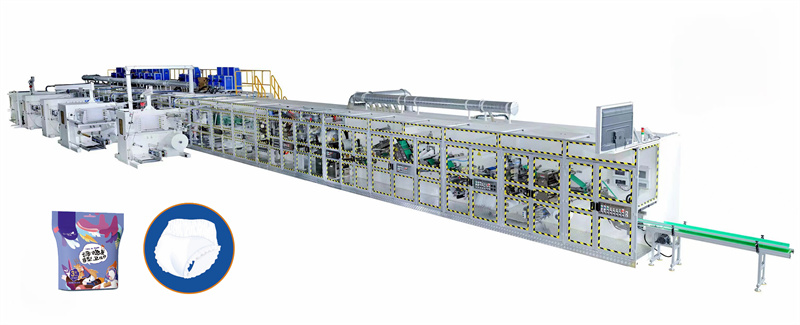

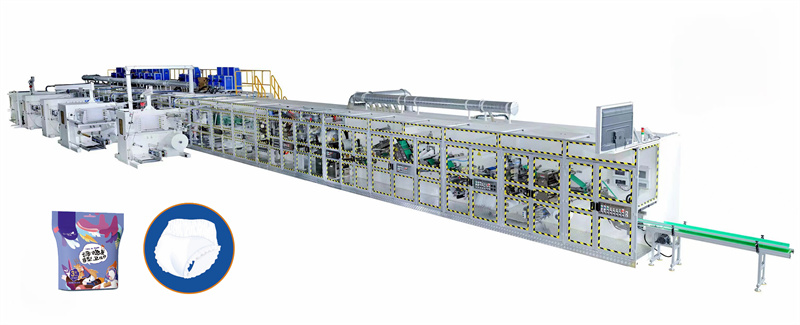

Overall Size:52x10x4.5(M) Machine Size:42x2.3x2.5(M) Design Speed:400pcs/min Stable Work Speed:300-350 pcs/min Product Yield:≥97% Powere Source:380V,50Hz Machine Capacity:Approx. 450KW Air Pressure:0.6—0.8MPa Machine Weight:Approx. 120T

|

Product specification: M: 660x580mm; L: 680x620mm

Product structure: Water repellent non-woven fabric; Hydrophilic non-woven fabric; Diversion non-woven fabric; Absorbent paper; Toilet paper; PE film; Core body non-woven fabric; Inner waistline non-woven fabric; Outer waistline non-woven fabric; Small envelope non-woven fabric; Waist rubber band

Control system: PLC control, touch screen operation man-machine interface, High-definition television display

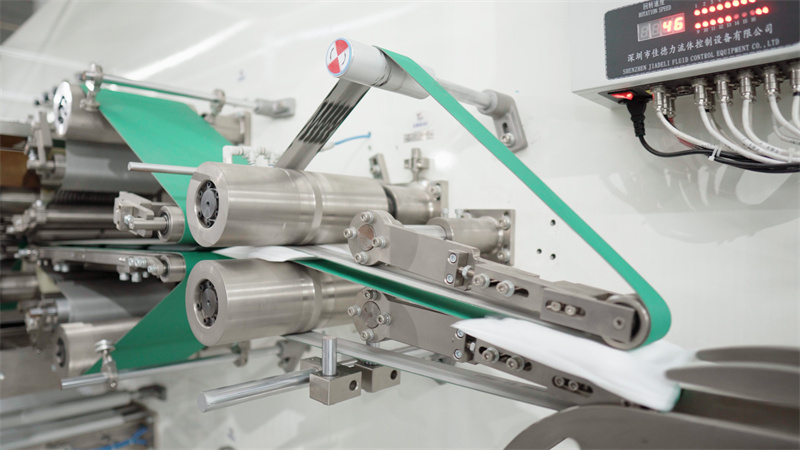

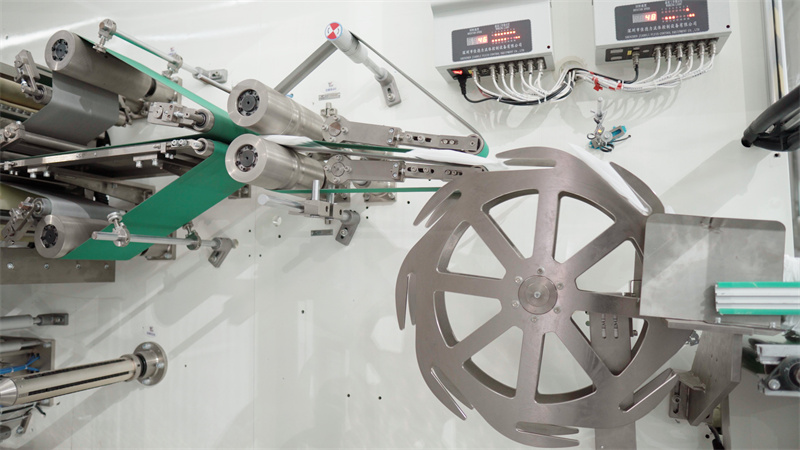

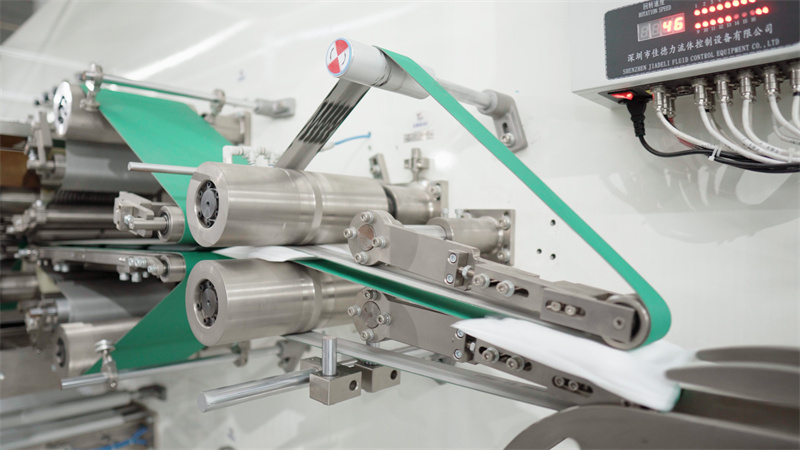

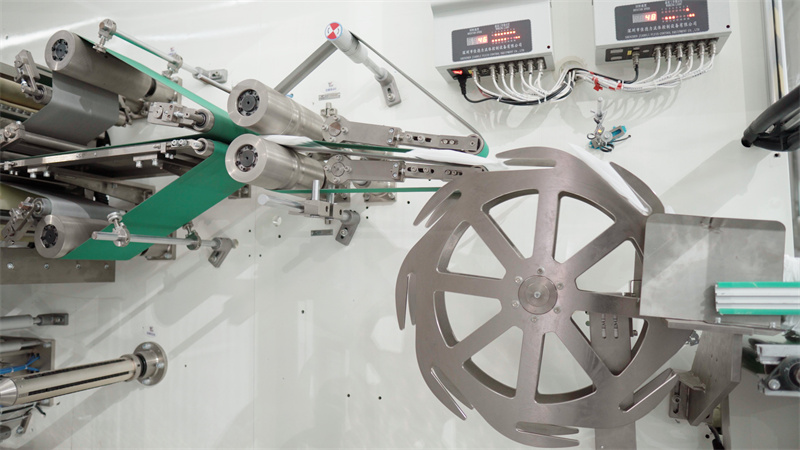

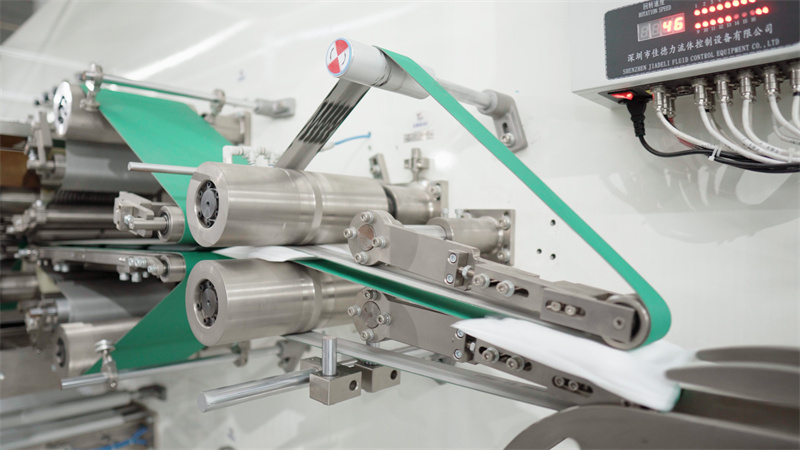

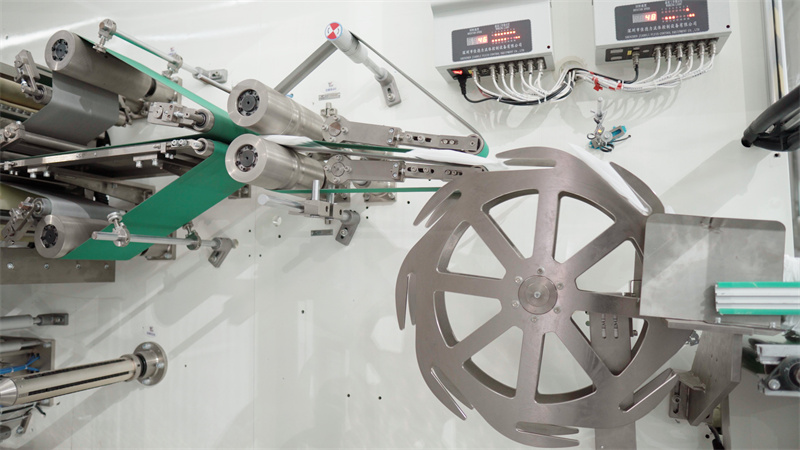

Transmission system: Servo transmission, synchronous belt using imported parts, and key parts using imported bearings.

Tension system: Equipped with tension uncoiling system, constant tension control and storage mechanism, and material correction system. This constant tension system ensures stable feeding at full speed, minimizes the impact on material tension, and reduces downtime.

Safety system: The operating surface is equipped with safety protection devices, emergency stop switches, and safety signs. The rear transmission is equipped with safety cables, and the high frequency fan adopts sound insulation or noise reduction devices.

Deviation correction system: BST correction device "optional"

Overall Size:52x10x4.5(M)

Machine Size:42x2.3x2.5(M)

Design Speed:400pcs/min

Stable Work Speed:300-350 pcs/min

Product Yield:≥97%

Powere Source:380V,50Hz

Machine Capacity:Approx. 450KW

Air Pressure:0.6—0.8MPa

Machine Weight:Approx. 120T

Product specification: M: 660x580mm; L: 680x620mm

Product structure: Water repellent non-woven fabric; Hydrophilic non-woven fabric; Diversion non-woven fabric; Absorbent paper; Toilet paper; PE film; Core body non-woven fabric; Inner waistline non-woven fabric; Outer waistline non-woven fabric; Small envelope non-woven fabric; Waist rubber band

Control system: PLC control, touch screen operation man-machine interface, High-definition television display

Transmission system: Servo transmission, synchronous belt using imported parts, and key parts using imported bearings.

Tension system: Equipped with tension uncoiling system, constant tension control and storage mechanism, and material correction system. This constant tension system ensures stable feeding at full speed, minimizes the impact on material tension, and reduces downtime.

Safety system: The operating surface is equipped with safety protection devices, emergency stop switches, and safety signs. The rear transmission is equipped with safety cables, and the high frequency fan adopts sound insulation or noise reduction devices.

Deviation correction system: BST correction device "optional"

中文

中文

中文

>

中文

>

中文

中文