|

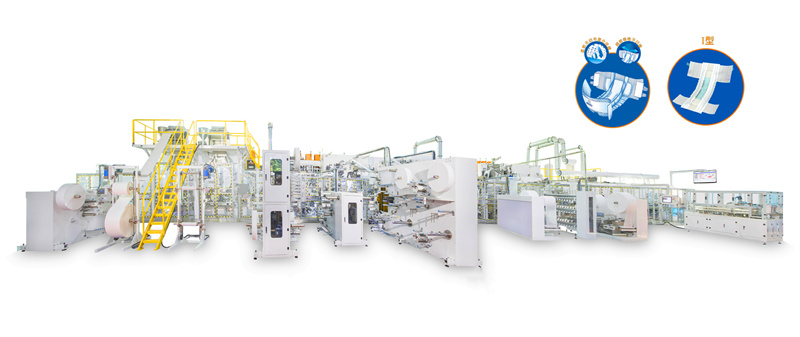

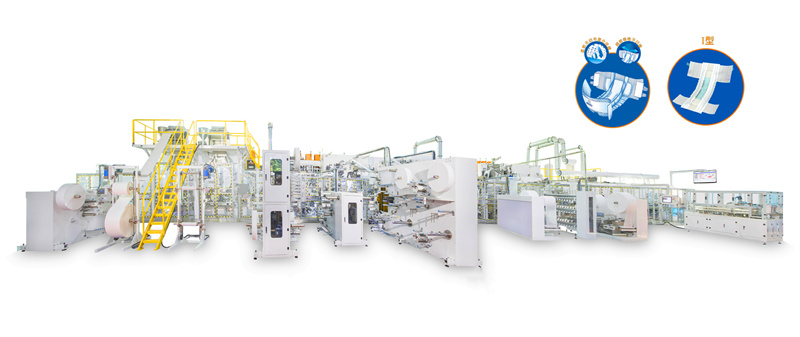

Overall Size:33x8x4.5(M) Machine Size:31x2.2x4.5(M) Design Speed:300pcs/min Stable Work Speed:180-250 pcs/min Product Yield:≥97% Powere Source:380V,50Hz Machine Capacity:Approx 400KW Air Pressure:0.6—0.8MPa Machine Weight:Approx 105T

|

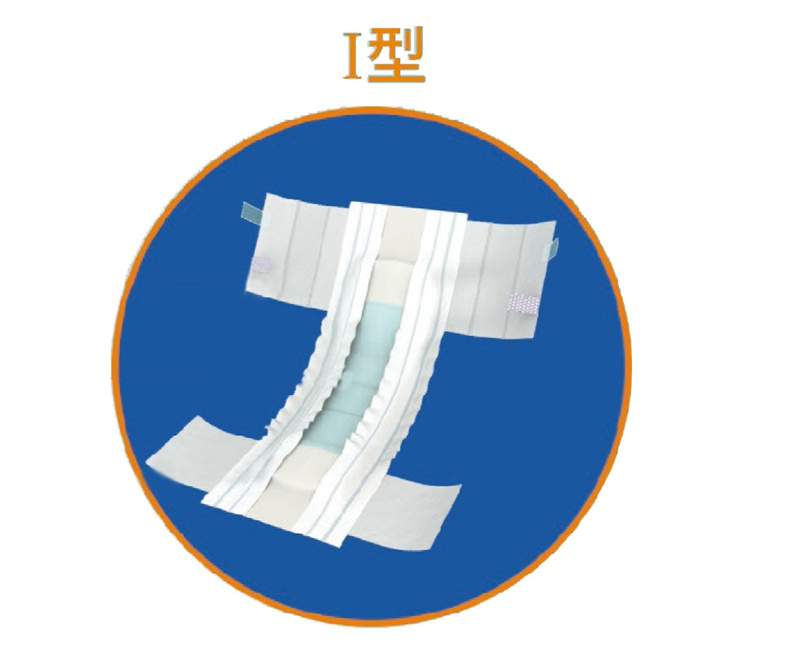

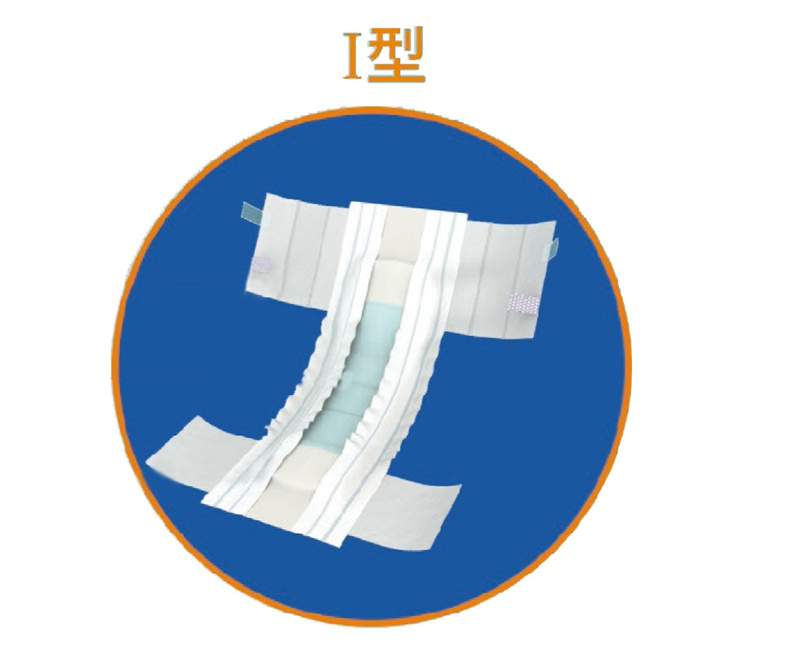

Production Size: M: 680 × 650mm L: 800 × 650mm XL: 950 × 760mm

Product Structure: Cotton core (SAP mixed), water based non-woven fabric (three-dimensional protection), surface non-woven fabric, diversion layer, leg rubber band, anti side leakage protection rubber band, bottom film, left and right waist patch, elastic waist patch, front waist patch

Control system: PLC control, touch screen operation man-machine interface, High-definition television display

Drive System: three Shaft-driven bicycle - full servo. The synchronous belt and flat belt synchronous belt adopt imported products, and key parts adopt imported bearings.

Tension System: Equipped with tension uncoiling system, constant tension control and storage mechanism, and material correction system. This constant tension system ensures stable feeding at full speed, minimizes the impact on material tension, and reduces downtime.

Safety System: The operating surface is equipped with safety protection devices, emergency stop switches, and safety signs. The rear transmission is equipped with safety cables, and the high frequency fan adopts sound insulation or noise reduction devices.

Materials Corrective System: BST corrector "optional"

Overall Size:33x8x4.5(M)

Machine Size:31x2.2x4.5(M)

Design Speed:300pcs/min

Stable Work Speed:180-250 pcs/min

Product Yield:≥97%

Powere Source:380V,50Hz

Machine Capacity:Approx 400KW

Air Pressure:0.6—0.8MPa

Machine Weight:Approx 105T

Production Size: M: 680 × 650mm L: 800 × 650mm XL: 950 × 760mm

Product Structure: Cotton core (SAP mixed), water based non-woven fabric (three-dimensional protection), surface non-woven fabric, diversion layer, leg rubber band, anti side leakage protection rubber band, bottom film, left and right waist patch, elastic waist patch, front waist patch

Control system: PLC control, touch screen operation man-machine interface, High-definition television display

Drive System: three Shaft-driven bicycle - full servo. The synchronous belt and flat belt synchronous belt adopt imported products, and key parts adopt imported bearings.

Tension System: Equipped with tension uncoiling system, constant tension control and storage mechanism, and material correction system. This constant tension system ensures stable feeding at full speed, minimizes the impact on material tension, and reduces downtime.

Safety System: The operating surface is equipped with safety protection devices, emergency stop switches, and safety signs. The rear transmission is equipped with safety cables, and the high frequency fan adopts sound insulation or noise reduction devices.

Materials Corrective System: BST corrector "optional"

中文

中文

中文

>

中文

>

中文

中文