|

Product Model:FT-1050B Max. Reel Dia.:1200mm Paper Core inner Dia.:76mm (3’’ shaft) Reel Paper Width:580-1050mm Printing Length:300-670mm Max. Printing Width:1050mm Max. Printing Speed:300m/min Slitting Size:250-670mm Max. Slitting Speed:700 cycles/min Page Counting :5-50 sheet/layer Cover Paper GSM:80-450g/m2 Cover Paper Size:250-670mm Folding Size:250-610mm Cross Cutting Size:580-1050mm Length Cutting Size:125-305mm Cutting Speed:45 cut/min

|

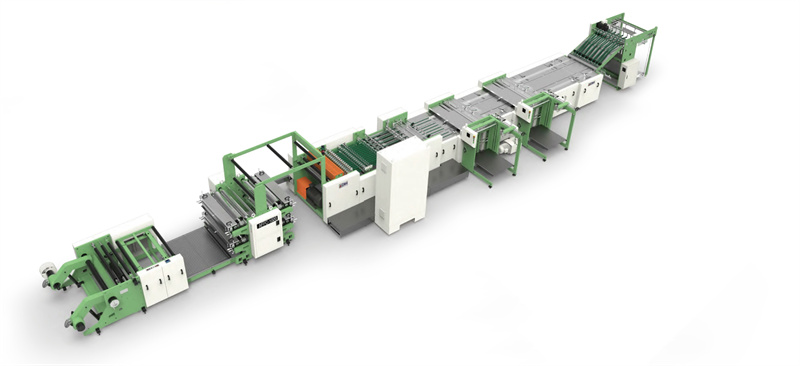

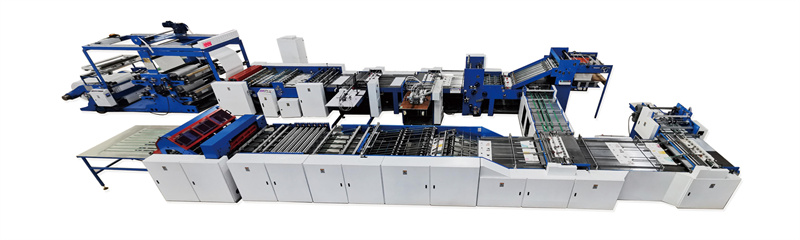

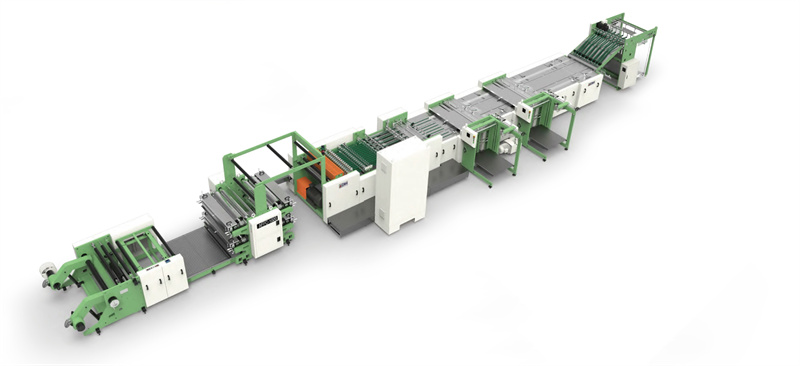

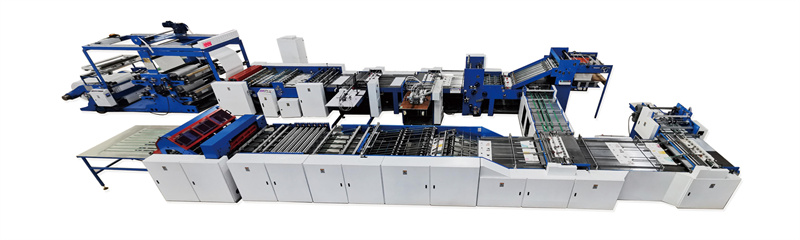

This machine utilizes advanced technology such as microcomputer controls, photoelectric tracking, hydraulic powered system, gas pressure devices, touch screen operation and water ink flexographic printing etc. Ink flexographic printing is environmentally friendly and scientific.

1.This equipment is assembled by one paper reel, 2/2 color printing tower (2 sides and 2 colors), paper slitting, page counting, high stack paper station, cross conveyor, cover feeder, folding, spine pressing, cross cutting, final trimming and finished product collection. The machine only requires a 4 person operating team. One senior operator and an assistant plus two for collecting and stacking the notebooks at the end of the machine. When making notebooks of less than 30 pages expect a production rate of 8000 to 10,000 notebooks per hour.

2.This equipment has the added versatility of being able to run as two separate units, or the full line machine operation. Separate operation including the front and back section. The front section can cover the operations like printing, page counting, cover feeding and high stacking of product. The back section can cover the operations like auto feeding after binding, folding, spine pressing, 3-side book trimming, and finished product collection. When using the complete full line machine operation, it can realize full automatic production of wire stapled exercise books.

Product Model:FT-1050B

Max. Reel Dia.:1200mm

Paper Core inner Dia.:76mm (3’’ shaft)

Reel Paper Width:580-1050mm

Printing Length:300-670mm

Max. Printing Width:1050mm

Max. Printing Speed:300m/min

Slitting Size:250-670mm

Max. Slitting Speed:700 cycles/min

Page Counting :5-50 sheet/layer

Cover Paper GSM:80-450g/m2

Cover Paper Size:250-670mm

Folding Size:250-610mm

Cross Cutting Size:580-1050mm

Length Cutting Size:125-305mm

Cutting Speed:45 cut/min

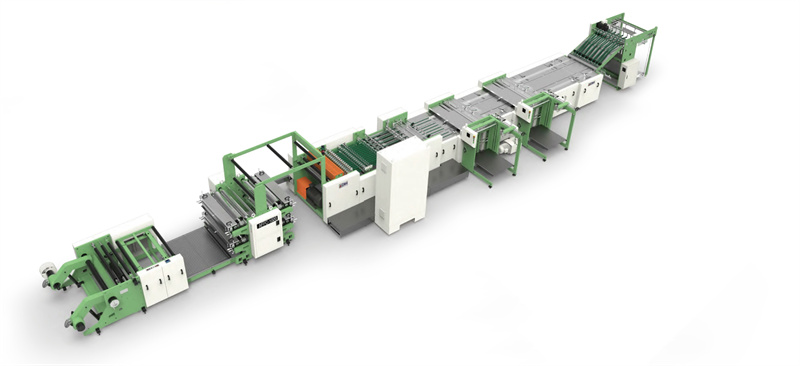

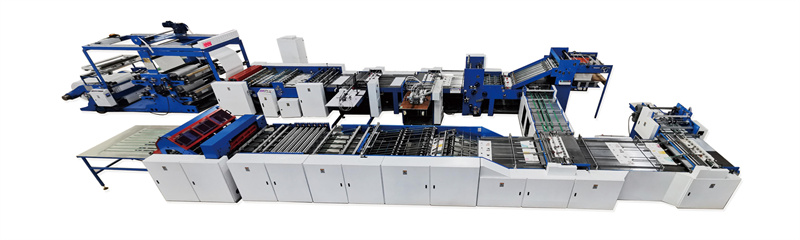

This machine utilizes advanced technology such as microcomputer controls, photoelectric tracking, hydraulic powered system, gas pressure devices, touch screen operation and water ink flexographic printing etc. Ink flexographic printing is environmentally friendly and scientific.

1.This equipment is assembled by one paper reel, 2/2 color printing tower (2 sides and 2 colors), paper slitting, page counting, high stack paper station, cross conveyor, cover feeder, folding, spine pressing, cross cutting, final trimming and finished product collection. The machine only requires a 4 person operating team. One senior operator and an assistant plus two for collecting and stacking the notebooks at the end of the machine. When making notebooks of less than 30 pages expect a production rate of 8000 to 10,000 notebooks per hour.

2.This equipment has the added versatility of being able to run as two separate units, or the full line machine operation. Separate operation including the front and back section. The front section can cover the operations like printing, page counting, cover feeding and high stacking of product. The back section can cover the operations like auto feeding after binding, folding, spine pressing, 3-side book trimming, and finished product collection. When using the complete full line machine operation, it can realize full automatic production of wire stapled exercise books.

中文

中文

中文

>

中文

>

中文

中文